IBC Heating

IBC Heating Solutions

Thorne & Derrick International are the UK’s leading specialist distributor of IBC Heaters, including IBC Heating Jackets and IBC Water Tank Heaters, trusted across industries such as process manufacturing, food & beverage, confectionery, chemicals, pharmaceuticals, and utilities.

We supply the widest range of high-performance IBC heating solutions to control temperature, prevent freezing, and reduce viscosity in bulk containers and Intermediate Bulk Containers (IBCs). Our heaters ensure safe and efficient thermal management—whether in standard or hazardous (ATEX) environments.

With the UK’s largest stockholding of IBC heating jackets, drum heaters, gas cylinder warmers, heat trace cable and tank heating systems, we offer rapid delivery, technical expertise, and a dedicated Exports Department for fast worldwide shipping and support.

Need help selecting the right IBC heating solution?

Whether you need IBC heating jackets, ATEX-certified IBC heaters, or custom solutions for complex or hazardous environments, our technical experts are here to help.

Speak to our team today for guidance on:

-

Sizing and compatibility for 1000L IBCs or custom containers

-

Choosing between standard, insulated, or base heaters

-

ATEX certification and temperature control requirements

Our IBC heating jackets are available in three power configurations to suit a range of temperature control needs. Choose from 1kW

(110V/230V) models with a thermostat range of 0–40°C, 2kW (110V/230V) models with an extended range up to 90°C, or 3kW (230V only) heaters for rapid heating and higher process demands.

Specialist IBC Heating Jackets – Standard & ATEX Applications

Thorne & Derrick supply specialist electric heating jackets for IBC containers and IBC water tanks, including models certified for Hazardous Area Zone 1 and Zone 2 use under the ATEX Directive. These heaters ensure safe temperature control for potentially explosive atmospheres, in line with UK HSE guidance (HSG51) for flammable liquid storage.

Our thermostatically controlled heating jackets deliver uniform surface heat up to 220°C, ensuring contents remain free-flowing and frost-protected — without the risk of hot or cold spots.

We also offer low-voltage heating jackets compliant with 17th Edition SELV (Separated Extra Low Voltage) regulations for added safety in sensitive or mobile applications.

Trusted Quality. T&D IBC Heaters: Made In The UK, Supplied Globally

IBC Heater Applications & Compatibility

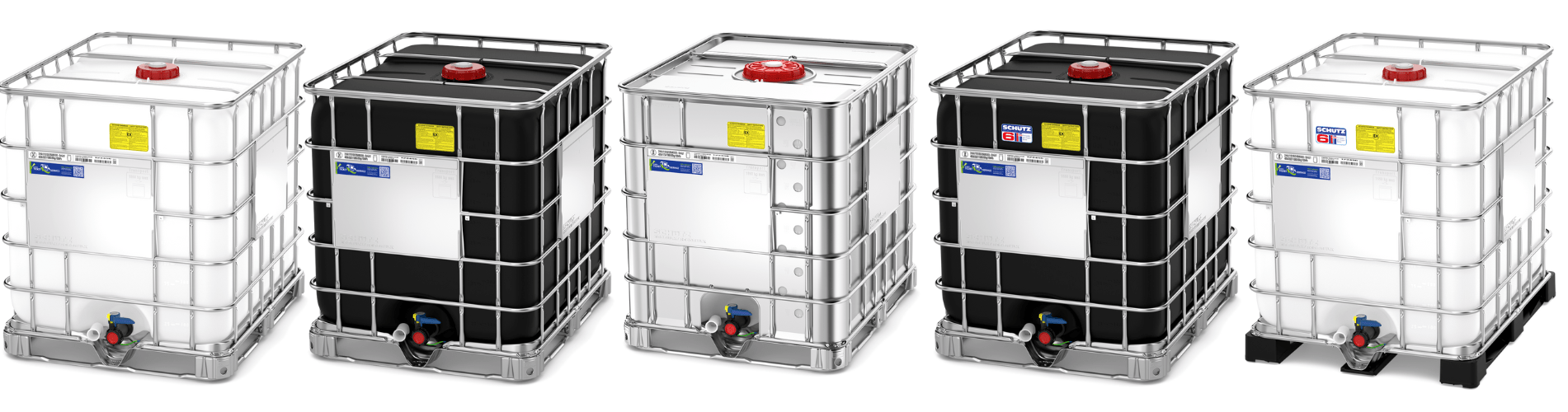

Intermediate Bulk Containers (IBCs) — also known as totes, pallet tanks, or tote bins — are widely used for the storage and transport of bulk liquids and granular materials across a range of industries.

Our IBC heaters are suitable for:

-

Chemicals, solvents, detergents, oils, sugars, cosmetics, crop science, and more

-

Compatible with IBC brands like SCHÜTZ, Francis Ward, Ragus, Pallecon, and Hoyer

-

SCHÜTZ ATEX IBCs are supported with compatible ATEX heater jackets for explosive atmospheres

Heating Jacket Specification

Explore our IBC heating jacket specifications below to compare available configurations.

Choose from 1kW, 2kW, or 3kW models with a range of voltage options and adjustable thermostat settings—designed to meet your precise process heating requirements.

| Number of Heating Elements | Voltage | Jacket Thermostat Range | IP Rating |

|---|---|---|---|

| One (1kW) | 110V / 230V | 0 – +40°C | IP40 |

| Two (2kW) | 110V / 230V | 0 – +90°C | IP40 |

| Three (3kW) | 230V | 0 – +90°C | IP40 |

T&D can deliver from stock compatible IBC Heaters and Heating Jackets to suit all brands of IBC to ensure free flowing or viscous liquids, granular, powders or semi solids – including ATEX certified IBC’s heater for hazardous areas.

Used to provide surface heating to containers storing highly viscous fluids such as sugar, sugar substitutes and sugar alcohols including Maltitol.

Our heating jackets enable safe and reliable heating of high-viscosity materials such as sugar alcohols (e.g., Maltitol), syrups, and gels — even in outdoor and sub-zero conditions.

SCHÜTZ produces ATEX IBCs, which are specially designed to safely handle hazardous materials in potentially explosive atmospheres

How IBC Heaters Reduce Viscosity & Improve Flow

Many industrial liquids become highly viscous at ambient temperatures — especially sugars, oils, surfactants, and process chemicals. Without heating, fluid flow slows dramatically, especially as container volume decreases.

IBC heating jackets:

-

Lower viscosity for faster, consistent discharge

-

Maintain material flow and prevent solidification

-

Improve process yield and reduce waste

We offer both standard and ATEX-certified solutions depending on your location and hazard classification.

ATEX IBC Heating for Hazardous Zones

T&D supply ATEX-certified IBC heating jackets for use in:

-

Zone 1 and Zone 2 classified hazardous areas

-

Oil & gas, petrochemical, offshore, and pharmaceutical sectors

We can design and manufacture bespoke IBC heaters on request, tailored to non-standard containers or site-specific requirements. For additional frost protection or process heating in explosive areas, we also supply heat tracing systems for connected pipework and tanks.

Custom IBC Heating Solutions – Built to Spec

With over 40 years of industry experience, our team provides:

-

Custom heat loss calculations

-

Tailored recommendations for heating and insulation

-

Fast UK & global delivery

-

Expert support from initial enquiry through to installation

We supply electrical heating systems for both standard and non-standard drums and IBCs, supporting a wide range of industrial and hazardous environments.

As the leading supplier in Europe of Electrical Heating Products for storage containers including drums and IBC’s, we have developed reliable heaters for a complete range of process heating and frost protection applications including:

| Application | Solution | Industry |

|---|---|---|

| Maintain fluidity of shotcrete outdoors | 1000L IBC Heater Jacket 110V, 0–40°C Thermostat | Construction (Tunnels & Shafts) |

| Heat peppermint cream for animal feed | 200L Drum Heater Jacket 230V, 0–90°C Thermostat | Agriculture (Feed Supplements) |

| Temperature control of vape liquids | 105L Drum Heater Jacket 230V, 0–90°C Thermostat | Manufacturing (Vape Labs) |

IBC Heating FAQs

Q1: What is an IBC Heater and how does it work?

IBC heaters are used to maintain the temperature of materials stored in Intermediate Bulk Containers. Learn how they work and which types are available.

Q2: Can IBC heaters be used in hazardous areas?

Some IBC heaters are suitable for hazardous environments. Discover the certifications and models designed for these applications.

Q3: How do I choose the right IBC heater for my application?

Contact our technical team—we’ll assess your requirements including environment, material, and process temperature to recommend the best solution.

➡ For complete specifications, ordering details and hazardous area certifications about IBC Container Heaters please refer to the product sections below.